Plastic parts manufacturing companies in china tell you what are plastic injection molds

Plastic over time has become one of the most essential materials in the life of all people, since it has a high capacity to be molded and adapt to any shape that comes its way.

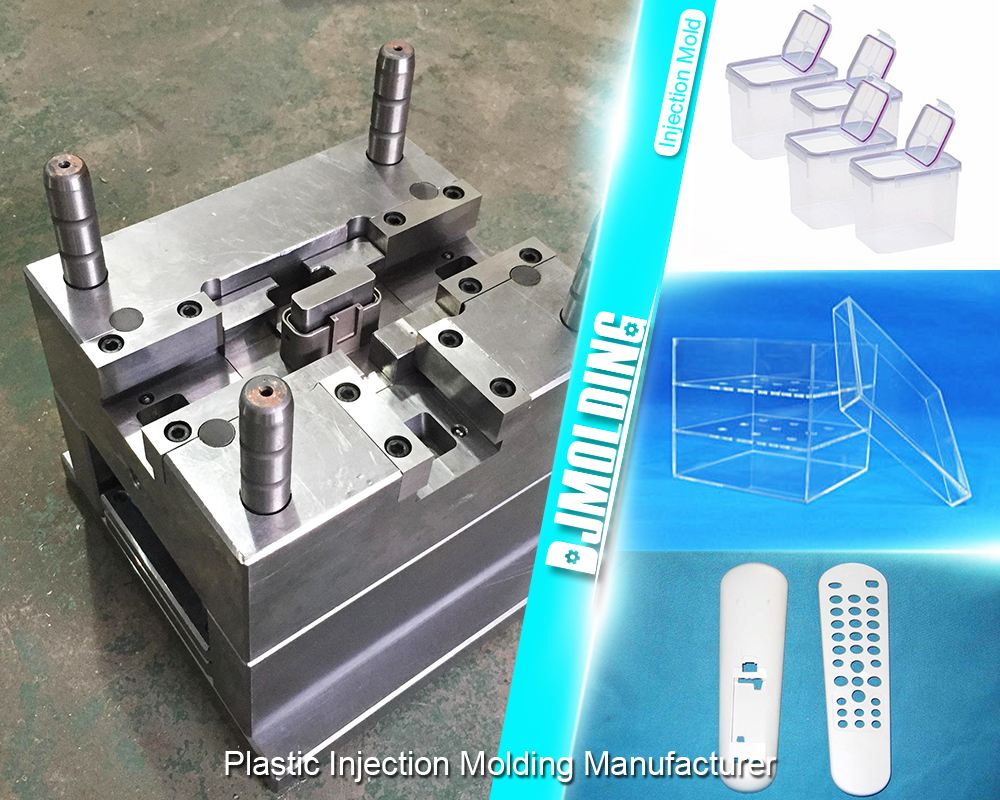

In order to make the shapes we want with plastic, it is necessary to use processes such as injection molding, being one of the most popular techniques for the manufacture of plastic figures or pieces.

One of the advantages of this process to make plastics is that it is not necessary to do an exhausting job, since it allows to make a variety of objects from a single piece, such as textures, colors, etc.

If you want to know more about this injection process, you can continue reading through this post to find out what it consists of.

What is an injection mold?

It has been the most important part in an injection process, that is, without a mold there can be no injection. This mold is where the piece will achieve a final shape and finish. It consists of two completely equal parts that at the time of injection are hermetically joined.

Each part of the molds must be filled with the hot plastic fluid and they are hermetically joined, in this way the shape can be made and the corresponding replicas of each object can be made. The molten plastic will be pressed with the injection machine so that the fluid reaches all the parts of the mold and wait for it to cool down.

It is very important that the mold that is intended to be used for an injection process is of very good quality and with a long useful life. Keep in mind that among the most important steps to make high productions of a plastic object with excellent finishes is the presence of a mold and that it meets the required measurements of the object to be molded.

It must be known that the materials with which the mold has to be made must allow it to have supports and resistance to compression, temperature, abrasion, chemical resistance and good thermal conductivity.

The molds used for injection can be interchangeable, screwed and unscrewed from the press, in this way many objects of different shapes can be achieved.

What are the parts that make up the mold?

- Channels: where the molten plastic travels to enter the mold cavities.

- Cavity: where the molten plastic is injected and deposited to finally create the piece.

- Respirators: these are the areas where the air circulates inside the mold and can cool the plastic.

- Cooling system: ducts through which coolant air, water or oils circulate, in this way it will ensure that the piece comes out perfect and that it will not suffer deformations.

- Bolts: being those that eject the molded part when opening the molds.

What are the plastics used for injection?

There are a variety of plastics that can be worked in different ways, so when making injection molds, plastics that are better for this process should be used.

- High-density polyethylene: a versatile and rigid plastic. It is used for the manufacture of various objects such as soda drawers, water pipes or even toys.

- Polyvinyl chloride of vinyl: this type of plastic allows to obtain a variety of objects such as credit cards, toys, chemicals or even window frames.

- Low density polyethylene: a rigid and crystalline material, it also has a high chemical resistance. With this material you can get a variety of items such as cookie or snack wrapping, parts for cars, disposable syringes, chairs and tables.

- Poly-styrene: high-gloss material with high impact resistance, they are also easily moldable through the injection process, dairy and disposable containers, food trays, thermal glasses, bookstore items and toys can be made.

Each type of plastic fulfills specific functions depending on the purpose of the objects to be manufactured.

For more about plastic parts manufacturing companies in china tell you what are plastic injection molds,you can pay a visit to Djmolding at https://www.djmolding.com/about/ for more info.

The post Plastic parts manufacturing companies in china tell you what are plastic injection molds appeared first on Plastic Injection Molding Manufacturer.